(Download) UPSC IES Exam Paper - 2018 "Mechanical Engineering

Paper - II"

Exam Name: Engineering Services Exam (IES)

Paper : Mechanical Engineering Paper - II

Year: 2018

File Type: PDF

MECHANICAL ENGINEERING

PAPER-2

Time Allowed : Three Hours

Maximum Marks : 300

QUESTION PAPER SPECIFIC INSTRUCTIONS

Please read each of the following instructions carefully

before attempting questions

There are EIGHT questions divided in two Sections.

Candidate has to attempt FIVE questions in all.

Question Nos. 1 and 5 are compulsory and out of the

remaining, any THREE are to be attempted choosing at least ONE

from each Section.

The number of marks carried by a question/part is indicated against it.

Wherever any assumptions are made for answering a question, they must be

clearly indicated.

Diagrams/Figures, wherever required, shall be drawn in the space provided for

answering the question itself.

Unless otherwise mentioned, symbols and notations have their usual standard

meanings.

Psychrometric Chart is given in Page No. 8.

Attempts of questions shall be counted in sequential order. Unless struck

off, attempt of a question shall be counted even if attempted partly.

Any page or portion of the page left blank in the QCA Booklet must be clearly

struck off.

Answers must be written in ENGLISH only.

SECTION-A

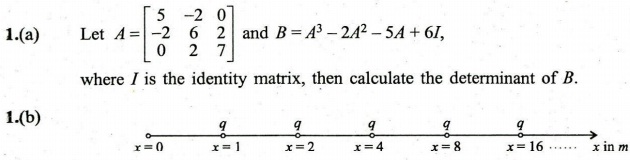

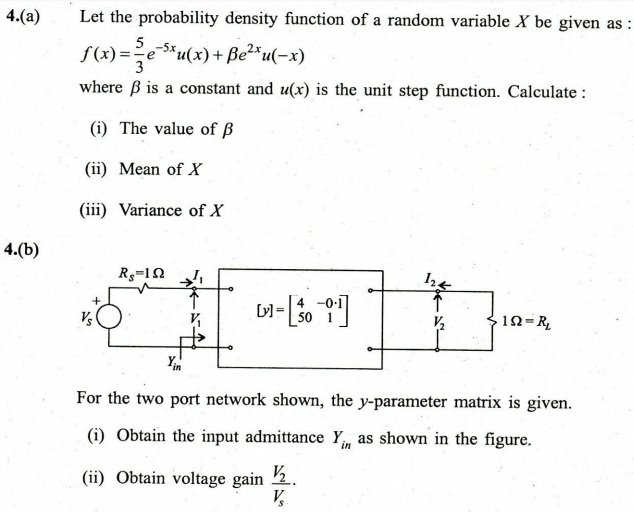

Q1. (A) (i) A flue pipe in a furnace system is rigidly

attached to the furnace wall at P, as shown in the figure below. Compute the

moments at points P1 and P2 when a force of 300 N is

acting at the end of the pipe.

(ii) Consider a solid block of mass 'm' resting on a

horizontal surface. When the mass is subjected to a horizontal force 'P' it will

experience a frictional force resisting the motion. Draw and show the variation

of frictional force F vs. applied force P even if it continues to shift from no

motion (static friction) domain to motion domain (kinetic friction).

(B) Draw and show the bending moment diagram and shear force

diagram of a beam of length 'L' subjected to a uniformly distributed loading for

the following boundary conditions:

(i) Cantilever beam

(ii) Simply supported beam

(iii) Beam with both ends fixed

(iv) Beam with one end simply supported and a propped support at 1/4th L from

the other end

(C) (i) Distinguish and differentiate between machine and

mechanism. Define the term Inversion of a kinematic chain.

(ii) Discuss about the possible inversions (with figures) of

a four bar chain.

(D) Derive the equation for the resultant unbalanced force at

any instant of a reciprocating mass of a slider crank mechanism.

(E) In a pair of mating spur gears, the pitch-diameter of

smaller gear is 120 mm. The pair is of standard gear involute having module as

8. If the transmission ratio between the gears is 4:3, then find out

(i) Number of teeth on gear,

(ii) Number of teeth on pinion,

(iii) Addendum,

(iv) Dedendum,

(v) Whole depth, and

(vi) Clearance.

Q2. (A) Compute the velocity and acceleration of the slider

in the quick return mechanism shown in the figure below, if the crank rotates at

30 rpm.

(B) (i) Draw and show the variation of centrifugal force and

controlling force of a governor.

(ii) Define Stability, Sensitivity, Isochronism governor. and

Hunting in a

(C) The data for 2 sets of spur gears are given below :

Check for the occurrence of Interference. If it occurs, what

is the pressure angle to correct it?

(D) (i) A single degree of freedom system is subjected to an

external harmonic force F(t) = F, sin wit. Define magnification factor (MF) and

plot it as a function of damping factor as it varies with respect to frequency

ratio.

(ii) A machine part having a mass of 2.5 kg vibrates in a

viscous medium. A harmonic exciting force of 30 N acts on the part and causes a

resonant amplitude of 14 mm with a period of 0.22 seconds. Find the damping

coefficient.

Q3. (A) (i) Define, discuss and differentiate :

(A) Centers of mass vs Centroid

(B) Mass Moment of Inertia vs Area moment of inertia

(C) Centroid of Lines, Areas and Volumes

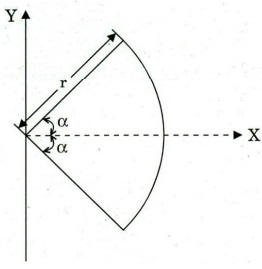

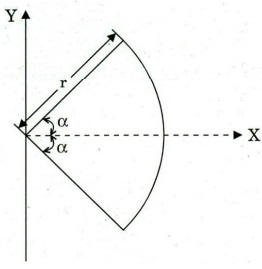

(ii) Locate the centroid of a circular arc as shown in the

figure below:

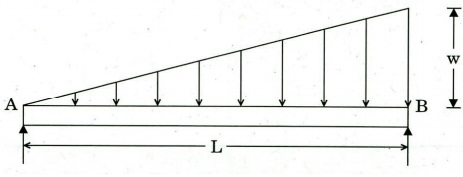

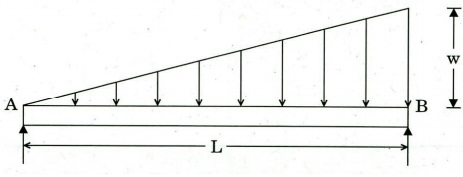

(B) Draw the Shear Force Diagram and Bending Moment Diagram

of a simply supported beam carrying a uniformly varying load from zero at one

end to 'w' per unit length at the other end. Compute the maximum B.M and its

location.

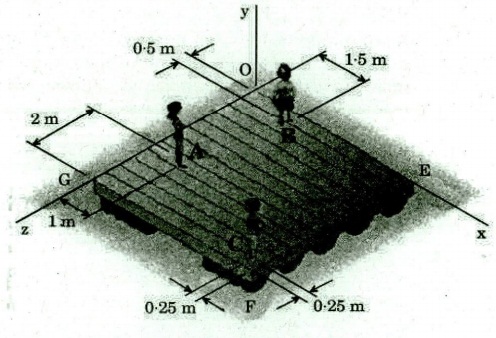

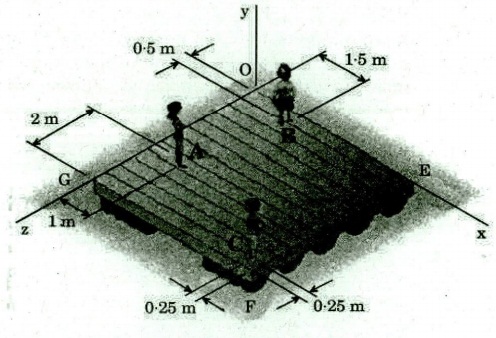

(C) (i) Three children are standing on a 5 m x 5 m raft as

shown in the figure below :

The weights of the children at points A, B and C are 375 N,

260 N and 400 N, respectively. Determine the magnitude and the point of the

resultant of their weights.

(ii) In a two dimensional system acted by various forces as

specified below :

Draw the free body diagram and equation defining them.

(D) Two shafts of the material and of same lengths are

subjected to same torque. If the first is of a solid circular section and the

second shaft is of hollow circular section, whose internal diameter is 2/3 of

the outside diameter and the maximum shear stress developed in each shaft is the

same, compare weights of the shafts.

Q4. (A) Differentiate between uniform pressure and uniform

wear theory. What would you conclude, about the effect over friction radius,

under following two conditions of operation of a clutch, considering uniform

pressure theory and uniform wear theory in both the conditions.

(i) Outer Radius - 100 mm

Inner Radius – 90 mm

(ii) Outer Radius – 100 mm

Inner Radius - 25 mm

(B) Design a flywheel for a single cylinder four-stroke

diesel engine, made of cast iron, whose allowable strength is 20 MN/m2. The

engine is running at a speed of 1400 r.p.m. and producing 5 kW of power. Maximum

peripheral speed of the flywheel may be up to 24 m/sec. Coefficient of

fluctuation of energy may be taken as 2.2 and coefficient of speed fluctuation

as 0.015. Density of cast iron may be taken as 7000 kg/m3. (The effect of

overhang of the flywheel on the end may be neglected.)

(C) Three M20 bolts are used to connect a steel plate with a

channel section structural member as shown in the figure. The material of the

bolt is 50C4 with o, = 660 MPa and oy = 460 MPa. Determine the factor of safety,

if the plate carries a load of 25,000 N at its end. Take area of M20 bolts as

245 mm2